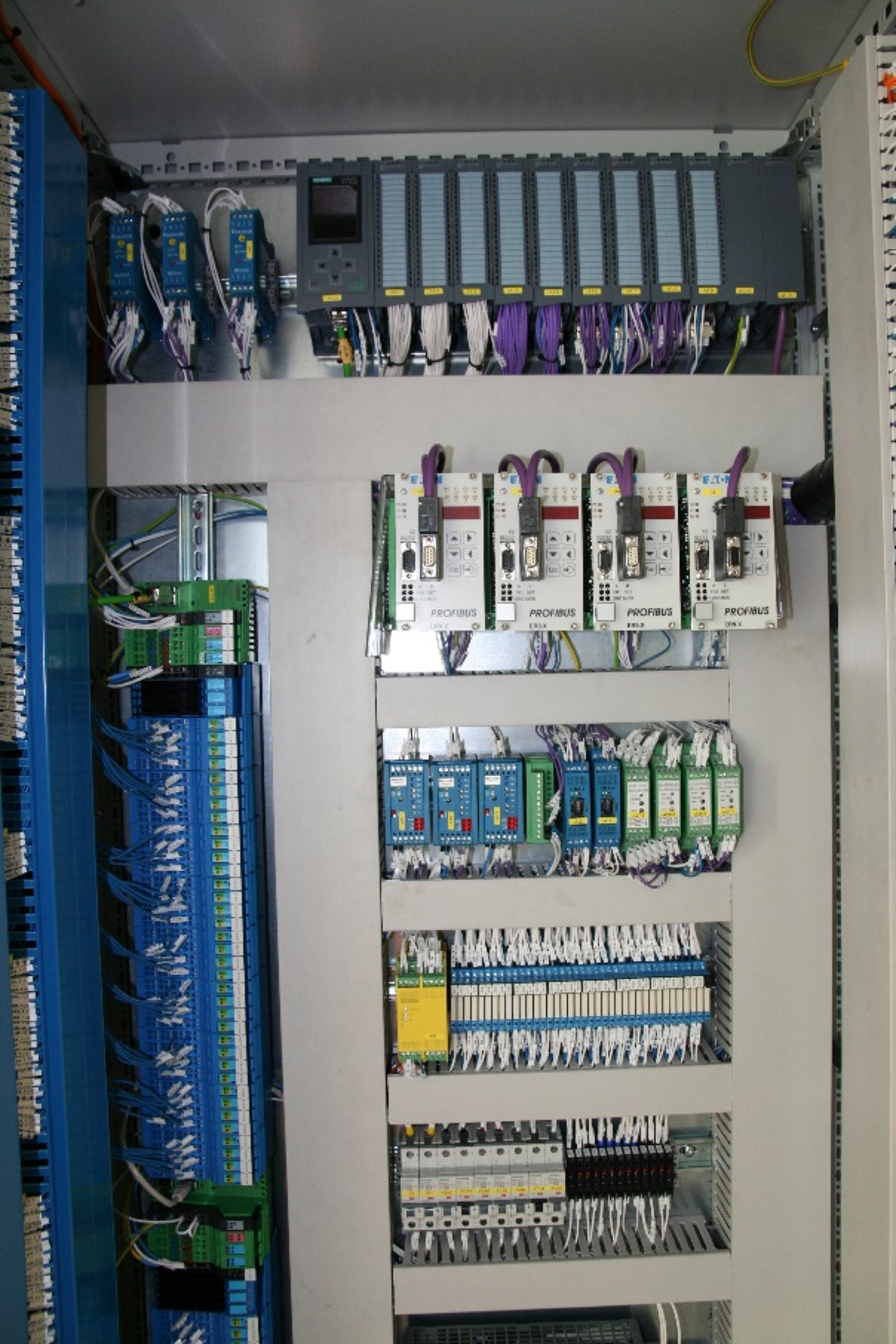

The power system, which consists of several main pumps, can be designed to support an assignment design where any of the pumps can individually be assigned to a specific machine. In this way, the power can be distributed where needed and according to the consumption requirement at the given time.

An automatic start-up procedure simplifies the operation process; first the feeder and servo pumps are started and pressure build-up is verified before the main pumps are activated. When all conditions are ready, the driller is notified and may commence operation.

The system can be integrated as part of the rig drilling system on the driller’s operating chair. This also includes a schematic visual representation of the HPU where the driller will have an overview of all the critical conditions, as well as an interface for assignment of each pump to a machine and the alarm system.

The HPU is built with specially designed hydraulic blocks, to reduce the number of fittings, pipe and tubing within the unit. This will give the unit a compact and service friendly design.