General information

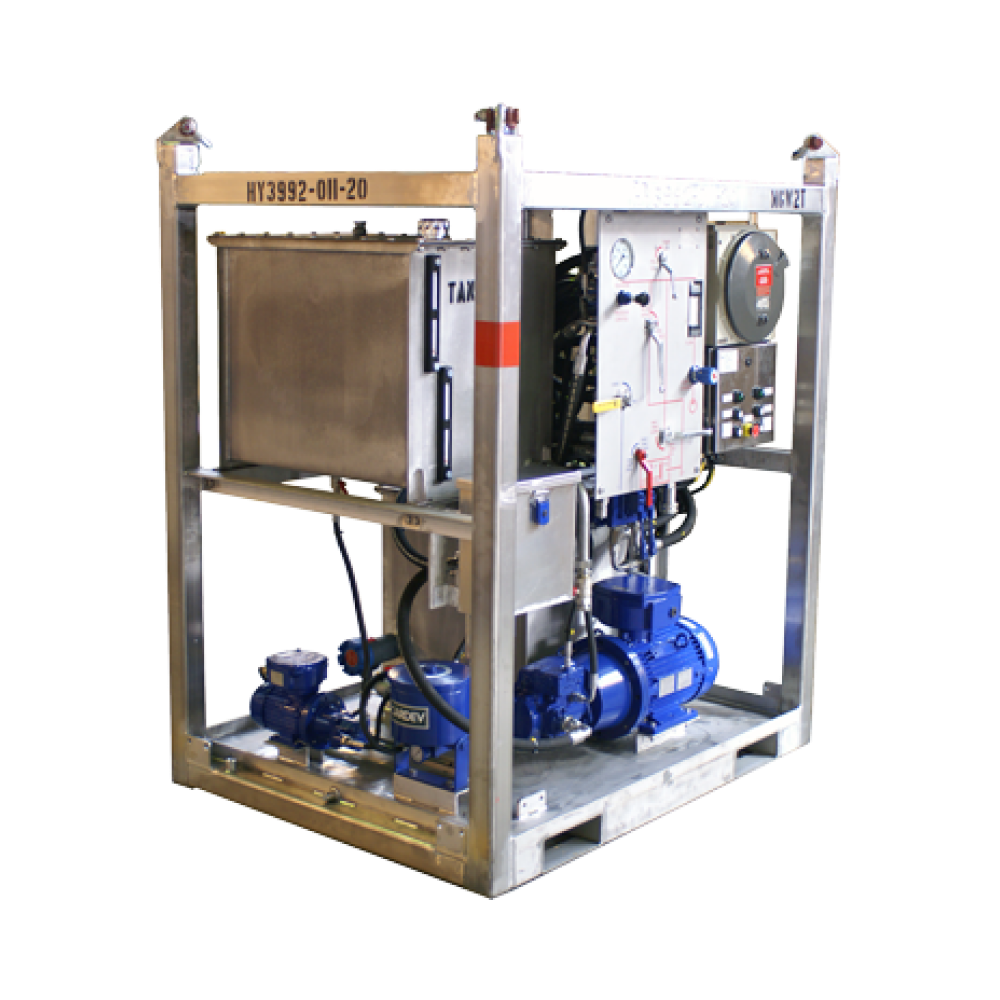

It is built for ease of transportation and easy hookup for use on a new location. It is built to be used in hazardous areas. It is designed around two electric driven hydraulic pumps with the best in terms of performance and reliability, long service intervals and high efficiency and are EX-certified.

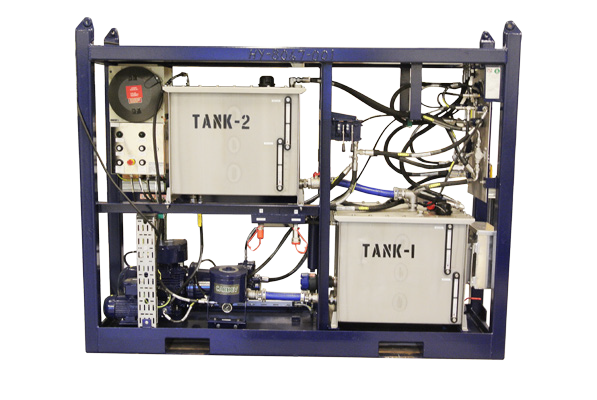

The system consists of two tanks made for hydraulic fluid, one ‘’clean’’ tank and one ‘dirty’ tank. The clean tank is where the oil is taken for the HPU and circulation purposes. The operator can then select the return to come back either to the same ‘clean’ tank or reroute it to the ‘dirty’ tank.

The dirty tank has connected a filtration circuit which clean up the oil and remove particles and water content if any before it route it back to the ‘clean’ tank for reuse.

Functional description

The Flushing unit have the possibility to work with the most common power voltage levels.

It has the possibility to adjust both the flow and the pressure for the flushing circuit. This to allow for low pressure and high pressure flushing tool dependent.

Features & Benefits

- Certified for lifting and transportation (designed according to DNV 2.7.1)

- Compact but still service friendly design.

- Can be utilized for many different hydraulic consumers and cleaning processes

- Easy to start up and operate.

- Quick connectors for the hydraulic supply and return interfaces.

- Setup for multi-voltage connections from 380 VAC and up to 690/VAC.

- Forklift pockets for ease of movement by forklift.

- Lifting lugs with shackles and chains for easy lifting by crane.

Interface information

The unit can be connected from bulkhead plate connectors:

HPU function interface

LS

Hatch Pump Load Sense port 3/8 BSP

P

Hatch Pressure port ½ BSP

T

Hatch Tank port ¾ BSP

Flushing function interface

T

Tank Port Male / HK HNV ¾”

P

Pressure Port Female / HK HNV ¾”

Specifications & Dimensions

The frame is built in accordance to DNV 2.7,1 standard. There are 4-part lifting lugs for connections of chains installed on the frame for transport use. Forklift pockets are placed in bottom part of the frame.

Tanks

Unit contains 2 tanks:

HPU / "clean" tank

Volume

210 l

Material

AISI 304

HPU / "dirty" tank

Volume

210 l

Material

AISI 304

Dimensions

Description

Lenght

2360 mm

Width

630 mm

Height

1900 mm

Max gross Weight

2000 kg

Get in touch

Please feel free to contact me by phone or by using the form below if you have any questions.

Cato Erga

CEO - Hytech Engineering & Services

Telefon

+47 982 56 637

E-post

cato@hytech.no